Q5D in the UK has raised $13.5m (£10m) to ramp up development of its robot system to automate automotive wiring harness production.

The $10.9m series A funding round brings the total backing to $16.7m, which also includes a £2m grant from Innovate UK for collaborative projects with several of the world’s leading automotive manufacturers and their tier-one suppliers at the company’s Technical Assessment Centre near Bristol.

The round was led by existing investors, Lockheed Martin Ventures, Chrysalix and Maven SWIF, with other investment from SOSV, UKI2S, UntroD and CPI Enterprises and follows £2m raised in February. The funding will support commercial pilots, team growth, and the build-out of additional manufacturing capacity as Q5D moves toward full-scale deployment with leading industrial partners and plans to raise a further funds in a corporate investment round later this year from potential customers.

Q5D is tackling the manual assembly of wiring harness systems in automotive, aerospace and consumer electronics. Constructing the harness by hand can be costly and error-prone and is often offshored to low-wage countries.

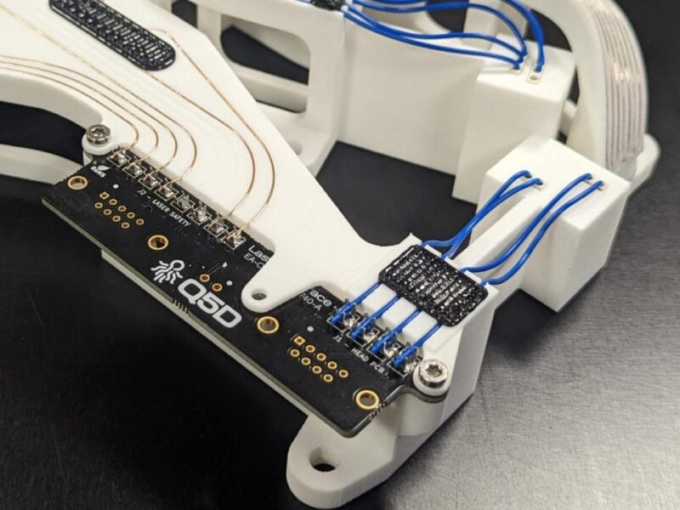

Q5D has developed a 5-axis manufacturing robot that can produce parts on demand and automate embedding wiring directly into the structure of a product and has no direct competition, says CEO Stephen Bennington.

- A unicorn for wiring harness automation

- Q5D appoints Scott White as chair

“With no direct competitors and significant technical barriers to entry our potential market is vast,” he said. “As vehicles become increasingly sophisticated in their electrical and electronics functionality, wiring complexity has reached the limits of what’s possible with conventional harnesses. In addition, the disruption of complex supply chains for vehicle wiring has cost carmakers billions of dollars in lost profits over recent years. Our technology will enable them to take back control of product electrification and it’s encouraging to see so many experienced investors recognising the tremendous positive impact it will have on that industry and others.”

You can read a more detailed interview with Bennington on eeNews Europe here.

The robots can be installed alongside the production lines, avoiding the current system of shipping harness assemblies around the different regions of the world. This helps to speed up final assembly and simplify supply chains, making them more resilient at a time of turbulence in global trade.

Using a wiring harness robot also reduces the need for local inventory and helps to give more flexibility for production lines. This could cut wiring costs by up to $200 for a compact vehicle, while enabling greater supply chain resilience.

“Our investment in Q5D and its automated electrification technology highlights our dedication to fostering a robust and resilient defense industrial base,” said Chris Moran, vice president and general manager of Lockheed Martin Ventures. “Through investments like this one, Lockheed Martin Ventures aims to accelerate the development of next-generation technologies that will enable our customers to stay ahead of emerging threats and maintain a strategic advantage in an increasingly complex security landscape.”

Leave a comment