ZF Friedrichshafen has presented a new generation of electric drives for passenger cars and light commercial vehicles. With the motors, inverters and mechanical modules as well as the associated vehicle software, the manufacturer wants to set new standards, especially with regard to power density and energy efficiency. To this end, the automotive supplier has implemented numerous innovations at the component as well as the system level. These include the compact design of the drives, a discrete approach to power electronics and a resource-saving use of materials, which also enables a more sustainable production of the drives. With this modular concept, the new e-drives are intended to support car manufacturers in the further electrification of their model range in a flexible and customised manner. For end customers, the new technologies offer higher efficiency, more power and shorter charging times, promises ZF.

- – Vitesco rolls new generation of electric axle drive

- – ZF furnishes electric drive axle for fuel cell bus

- – Software increases efficiency, battery life of commercial vehicles

With the new generation of its e-drives, ZF primarily wants to offer OEMs fully integrated electric drive systems. However, the Group will also offer the components individually. Customers can thus put together their own customised driveline systems. “Thanks to sophisticated internal interfaces, the new, extremely compact design allows system or component adaptations to be made with little effort. In addition, the design has a very high structural rigidity, which enables superior noise behaviour,” explains Dr Otmar Scharrer, Head of Development for Electric Drive Technologies.

The new generation of e-drives will be available on the market as a complete system from 2025; some individual components will be brought into series production earlier, the company said.

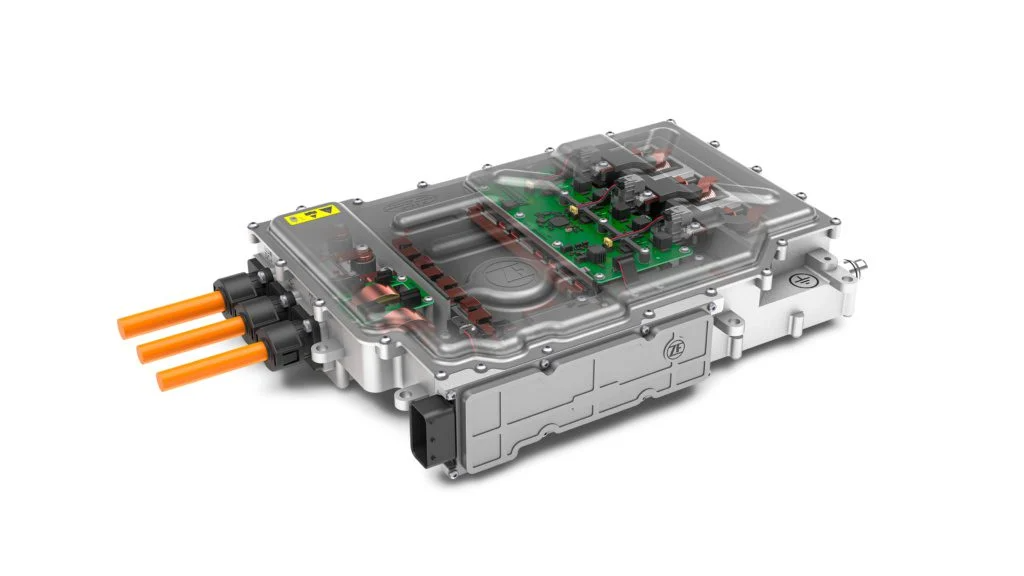

With the so-called “discrete package technology”, the power electronics subsystems manage the balancing act between a high degree of component uniformity and high adaptability. The individualisation takes place at the chip level: a discretely constructed IF inverter is built with individual power semiconductor switches. This modularity offers better performance scalability than is possible with complex power modules. In addition, this “discrete package technology” requires fewer different types of components than when using conventional power modules. High-voltage converters (DC-DC converters) play a central role in fuel cell-powered electric drives. They compensate for the low output voltage and the sharp drop in voltage when the fuel cells are under high load. The new high-voltage converter from the ZF power electronics platform, which was developed for passenger car and commercial vehicle applications, has a remarkable value of 99.6% in terms of efficiency. “With our new approach to power electronics, we can serve different market requirements faster and more precisely,” explains Scharrer.

With a new, highly integrated e-motor, ZF increases the power density compared to technology currently available on the market. The decisive role here is played by a new cooling concept and a new winding technology. With the cooling concept, ZF allows oil to flow directly around the copper rods – in other words, exactly at the point where the most heat is generated during operation. This makes it possible to significantly increase performance with the same weight and installation space. The continuous power of the electric motor is thereby brought up to 85% of the peak power. The high power density also aims to largely eliminate the use of heavy rare earths. The braided winding technology developed by ZF, a further development of the so-called “hairpin” winding, enables an overall installation space that is around 10% smaller. The winding head alone is about 50% smaller than with conventional approaches. This also saves raw material; according to the supplier, this saving is around 10%.

The new generation of drives also includes a coaxial reduction gear. With this, ZF wants to transfer its know-how in planetary gearboxes to the next generation of electric drives. Two planetary gears integrated into each other not only generate the desired axle ratio, but also include the fully integrated differential function. Compared to common offset concepts, the new solution reduces weight and installation space requirements without compromising on efficiency, noise and vibration.

Leave a comment